Request a Quote

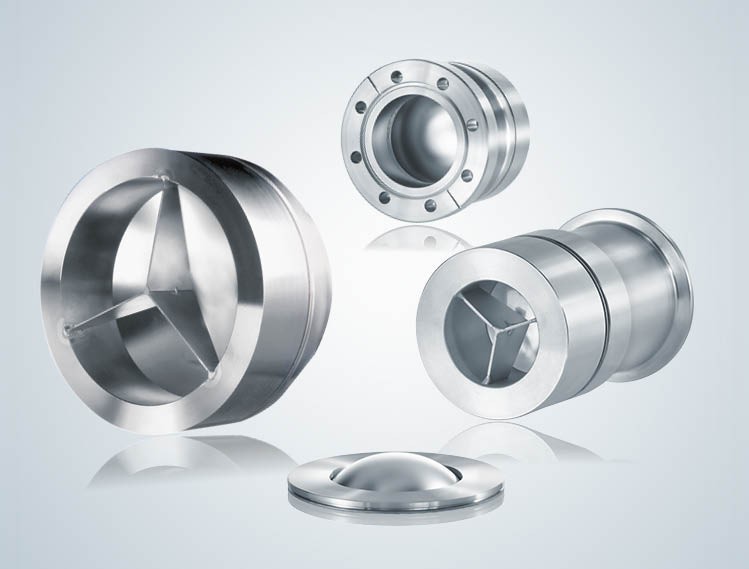

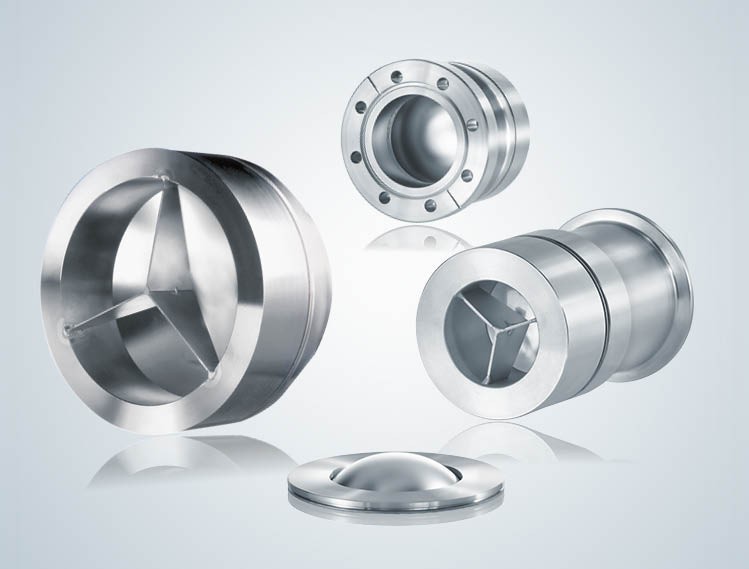

Witzenmann Rupture discs

Witzenmann France is the subsidiary of the Witzenmann Group dedicated to the global market. With more than 150 years of innovative experience as a Group and its reputation through its Hydra brand, Witzenmann has now established itself as the undisputed leader in flexible metal parts in all sectors of activity.

Rupture disc: Quality

| Quality is Witzenmann's priority objective, as evidenced by the numerous certifications (EN ISO 9001:2008, EN ISO 13485) and approvals (PED, ATEX, high pressure applications, ADR) that we have endeavoured to obtain.

Leader on the market of flexible metallic elements (piping, bellows, compensators) we are also a specialist in bursting discs. Witzenmann is the preferred partner of many major industrial companies.

|

|

Regulations: Directive 2014/68/EU

| Bursting discs used as safety accessories are, unless specifically excluded, subject to European Directive 2014/68/EU and classified in category IV. Our quality system, the design and manufacture of our discs are therefore regularly monitored by a notified body which ensures that our products comply with the essential requirements of this directive. |

Efficient pressure

| Maintenance Bursting discs manufactured by Witzenmann belong to the essential safety equipment of pressure equipment.

Designed according to specifications, in particular according to the expected bursting pressure, they break if the pressure is exceeded at a given temperature. They therefore avoid overpressure as well as the material damage and personal injury associated with great reliability.

Witzenmann designs and manufactures bursting discs specially adapted to the individual requirements of each project. They can also be integrated into pre-existing system configurations. |

Versions

- In stainless steel, nickel, or other materials

- Direct or inverse design

- Complies with European Pressure Equipment Directive 2014/68/EU

- According to EN ISO 4126-2 and EN ISO 4126-6

-

-

-

|

Efficient pressure

| Maintenance Bursting discs manufactured by Witzenmann belong to the essential safety equipment of pressure equipment.

Designed according to specifications, in particular according to the expected bursting pressure, they break if the pressure is exceeded at a given temperature. They therefore avoid overpressure as well as the material damage and personal injury associated with great reliability.

Witzenmann designs and manufactures bursting discs specially adapted to the individual requirements of each project. They can also be integrated into pre-existing system configurations. |

In addition

- Bursting discs are delivered with a suitable support

- Suitable for assembly by welding, screwing or clamping

- For protection against accidents linked to overpressure or in the event of failure of other safety devices

- Can be used with or without alarm device

- In double arrangement for continued operation

-

-

-

|

Direct Principle

| The operation of direct discs is based on the breaking strength of the material constituting the strip.

Accuracy: ± 10% for Pr > 1.5 bar // ± 15% for Pr ≤ 1.5 bar

Operating Pressure / Burst Pressure Ratio: 75% maximum

Resistance to fatigue (pressure cycles): Average to good

Vacuum resistance: Moderate to poor

Fragmentation: Yes for gas applications

Pressures: 1 to 1000 bar (depending on diameters)

Diameters: DN 5 to DN 400 (depending on pressures)

Materials: Austenitic stainless steels (1.4404, 1.4541, 1.4301). Nickel NI200, NI201 - Alloys with nickel base. All materials compliant with international standards and/or PED 2014/68/EU regulations

Temperature: -273°C to +650°C

|

|

REVERSE Priciple

| The operation of reverse discs is based on the resistance to buckling of the strip which is turned over and cut on a knife.

Accuracy: ± 10% for Pr > 1 bar // ± 15% for Pr ≤ 1 bar

Working Pressure / Burst Pressure Ratio: 75% maximum

Resistance to fatigue (pressure cycles): Excellent

Vacuum resistance: Excellent. Can also withstand back pressure greater than burst pressure.

Fragmentation: No for gas applications

Pressures: 0.4 to 40 b (depending on the diameters)

Diameters: DN 25 to DN 400 (depending on the pressures)

Materials: Austenitic stainless steels (1.4404, 1.4541, 1.4301).

Nickel NI200, NI201 - Nickel-based alloys.

All materials compliant with international standards and/or PED 2014/68/EU regulations.

Temperature: -273°C to +650°C

|

|

For more information: https://www.witzenmann.fr/fr/entreprise/witzenmann-france/